McCarthy

Environmental Ltd

Engineering Clean Air

Nationwide Design, Supply, Installation, Testing & Maintenance of fixed and portable LEV (Local Exhaust Ventilation) Systems

With over 20 years of experience, McCarthy Environmental Ltd have built an enviable reputation as a nationwide specialist provider of air pollution control solutions to industry, education and commercial workplaces.

We will design, install and commission a wide range of dust extraction systems, fume extraction systems and ventilation systems to meet your bespoke requirements. All our system designers are qualified to BOHS P602

Our installation teams are trained to the highest standards and hold all the latest certifications for safe working on customer sites. The company also holds CHAS accreditation.

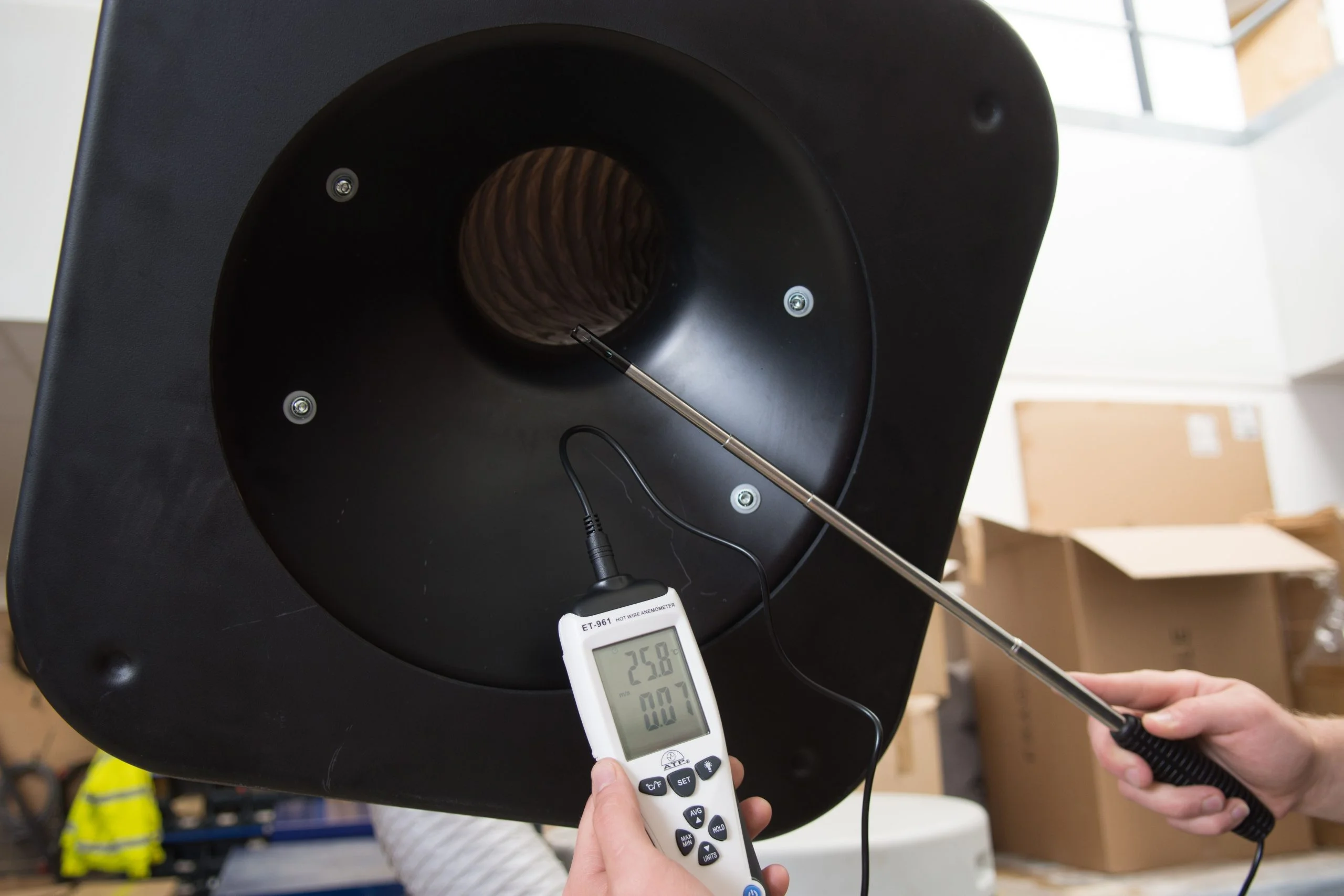

Our LEV test engineers are qualified to the latest BOHS P601 requirements as required by the standards of the HSE to carry out LEV testing (Local Exhaust Ventilation) which is a key requirement to ensure that both newly commissioned and existing systems continue to provide the optimum performance that will ensure protection for your workforce.

McCarthy Environmental Ltd offers a range of services which include:

- Design, supply, installation and commissioning of all types of LEV Systems

- A full occupational hygiene monitoring service for industry, including personal air monitoring and noise assessment in the workplace

- Scheduled maintenance programs

- Emergency repair service

- Supply and fitting of spare parts

Our quality range of products from manufacturers including ESTA, DUSTCONTROL, Nederman, BOFA, Filtermist, Airbench, Absolent, Kemper, and our bespoke manufacturing capability means we can offer a complete, cost-effective turnkey solution for all your dust and fume extraction requirements.